High-performance engineering plastics are plastics that can be used as engineering materials and replace metal-made machine parts. They have excellent comprehensive properties, high rigidity, small creep, high mechanical strength, and can be used for a long time in harsh chemical and physical environments. . The company has high-performance engineering plastics including: PA46, PPA, LCP, PET, PPS, PEEK, etc. These high-performance engineering plastics are mainly used in new energy vehicles, automotive wiring harnesses, metal replacement, gear transmission systems and other fields.

High performance engineering plastics are mainly used

● Electronic and electrical

● Optical fiber

● Metal substitution

● Cars and aerospace

Gear refers to the mechanical component that has gear connection on the rim to transmit motion and power. Compared with metal gears, plastic gears have lubricity and wear resistance, which can reduce noise, reduce cost and reduce friction. In terms of gear design, we can carry out gear contour design, meshing simulation and optimization, strength and service life verification, noise reduction and material selection suggestions, and various standard equivalent calculations according to different requirements put forward by customers. Customized service. Based on the gears of the design and the selected materials, the gear accuracy can be achieved:

In order to ensure the accuracy of the gear, we need to measure the gear, including: single gear measurement, base tangential length is tooth thickness, tip and root diameter, size on the needle or ball, composite measurement, dynamic double-sided test and main gear Wait for a series of measurement steps.

For gear molds, we can perform gear contour design, mesh simulation, optimize internal capabilities, plastic application work environment verification and gear contour equivalent calculation between different standards such as AGMA, DIN, JIS, GB.

DIN grade 8 (AGAM9, JIS3) {according to DIN58400 (m < 1) and DIN 867 (m > 1)}

Module < 1, pitch 25 mm

Fi "-60μm, fi"-22μm

Production of 8 and 16 cavity tools, Cpk=1.33

DIN grade 7 (AGAM10, JIS1-2) (according DIN58400 and DIN867)

Module < 1, pitch 25 mm

Fi "-25μm, fi"-9μm

Production of 2 cavity tools, Cpk=1.33

The pipe joint is a connecting tool between the pipe and the pipe, and is a connection point between the component and the pipe, which is an indispensable and important role in the pipe fitting. Pipe joints are often used in the inlet and outlet systems of engines and motors, as well as the joints of some engine cooling circulation systems. The materials require high corrosion resistance and high pressure resistance. We can achieve different angles and directions in production. Through the joint, we can achieve a maximum length of 600mm for the extension rod and a minimum level of 4mm for the inner hole.

Joints and fittings are mainly used

● Quick Connector

● Cooling system

● High pressure pump spool

● Expansion valve and other fields

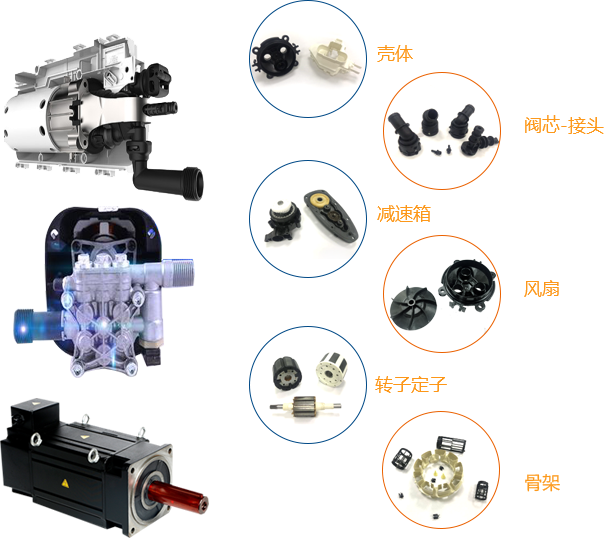

A servo motor is an engine that controls the operation of mechanical components in a servo system. It is an auxiliary motor indirect transmission. The servo motor can control the speed and position accuracy very accurately, and can convert the voltage signal into torque and speed to drive the control object. Our company mainly covers the following fields: servo motor motor bracket products, with high reliability and stability; servo motor motor fan products, using professional dynamic balance measuring instruments to effectively ensure the reliability of the overall performance of the fan. Pump valves are the collective term for pumps and valves. A valve commonly used for pumps or valves with pumping action. Our company mainly involves the following fields: joints and related parts around the pump body, water inlet and outlet joints to replace steel, pressure water gun joints and engineering development support with plastic-made steel to achieve the purpose of reducing the cost.

Motor and pump valve components are mainly used

● Servo motor rotor

● Terminal and skeleton

● Servo motor fan

● High pressure valve inlet and outlet parts

● Spool and nozzle

● Reduction unit

● Filter and water purification components